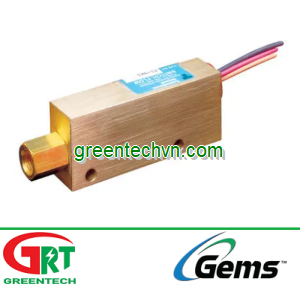

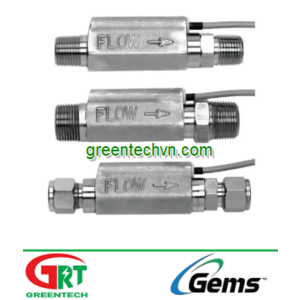

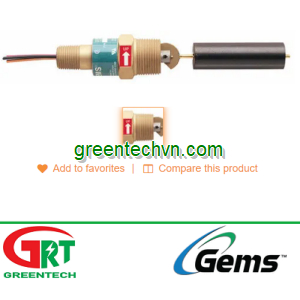

LS-7 Single-Point Type 8 Level Switch

LS-7 Series Single-Point Type 8 Level Switches are compact, durable alloy body switches with polypropylene or nylon floats, ideal for any small tank or vessel destined for a rugged environment. Ideal for Small Tanks1/2" NPTExternal Mounting